|

Hejian Perfect Drilling Equipment Co., Ltd.

|

| Price: | 500.0~1500.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

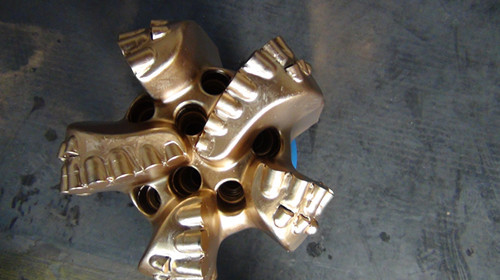

1)Features:

1. Cutting structure is force balanced and bit blade is asymmetrically designed so that the load on bit is balanced that resulting better stablity of the bit.

2. Main cutter is high performance PDC cutter to insure service life of the bit while improving ROP.

3. Cutter exposure is optimized to insure the bit can achieve higher ROP is soft to medium formations.

4. Shock absorbers are designed to make the bit capable of drilling through formations with hard strigers.

5. Hydraulic systems of the bit is optimized using dynamic flow pattern simulation technology enhance cleaning and cooling effects of the bit to effectively prevent bit from balling.

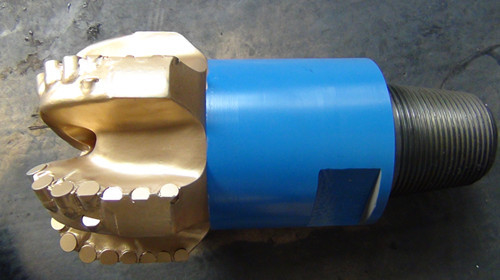

2)Product Size

5 1/2, 6 1/2 7 7/8, 8 1/2, 8 3/4 10 5/8, 12 1/4 13 3/4, 17 1/2, 22, 24, 26

IADC CODE

M223, M322, M316, M222, M416, M122

The Main Type Of PDC Bits:

Type | Blade | Cutter | Bit Size | Std. API pinShankSize(in) | Approximate WeightofBits(Kg) | ||

Inch | mm | ||||||

63/4 M | 5 | 16 | 63/4 | 171.5 | 31/2REG | 50 | |

77/8 M | 4 | 16 | 77/8 | 200 | 41/2REG | 65 | |

83/8 M | 6 | 16 | 83/8 | 212.7 | 41/2REG | 70 | |

81/2 M | 4 | 19 | 81/2 | 215.9 | 41/2REG | 70 | |

81/2 M | 5 | 16 | 81/2 | 215.9 | 41/2REG | 75 | |

81/2 M | 6 | 13 | 81/2 | 215.9 | 41/2REG | 80 | |

91/2 M | 5 | 16 | 91/2 | 241.3 | 65/8REG | 100 | |

91/2 M | 5 | 19 | 91/2 | 241.3 | 65/8REG | 100 | |

115/8 S | 4 | 19 | 115/8 | 295.3 | 65/8REG | 125 | |

121/4 M | 5 | 16 | 121/4 | 311.2 | 65/8REG | 130 | |

121/4 M | 6 | 16 | 121/4 | 311.2 | 65/8REG | 140 | |

121/4 S | 5 | 19 | 121/4 | 311.2 | 65/8REG | 130 | |

Our API Certification PDC Drill Bit for Petroleum Exploration is good in quality and competitive in price. We manufacture API Certification PDC Drill Bit for Petroleum Exploration and supply OEM, ODM service according to your requirement.

API Certification PDC Drill Bit for Petroleum Exploration has been presented above, want more similar products, please click PDC Oil Drill Bit.

Bit character

These types of bit have some common features, as follows:

1. Force balanced, resist impact to the blade during high-speed drilling, to make bit work stable.

2. Plus wear knot section, reduce collision in the high-speed rotational vibration.

3. Patented matrix formulation, extended bit life.

4. Optimal hydraulic design, easy to move out the drill cuttings and cooling.

5. Equipped with back reaming teeth.

6. The cutter is high performance to increase the ability of anti-impact and anti-abrasive

Features

It has a super long life. The useful life of the PDC bit is 4~5 times than the diamond bit, 10 times than the tungsten carbide bit at least.

It has high drilling speed.

It can be operated with low pressure and low speed.

It has a good gage protection.

It can be used widely, more suitable for drilling in the stratum with hardness coefficient

It has a low cost.

Advantage

higher nozzle counts and fixed ports to best serve cleaning cooling and cuttings evacuation requirement with available hydraulic flows.Allow higher flow rates with minimal increase in pump pressure.

Benefit:Optimized ROP and bit life Longer drilling intervals without need for tripping

PDC bits uses PDC as main cutting components, with the excellent wear-ability and impact toughness of the PDC.

It has a long useful life, high-efficiency, and good cost performance.

PDC bit is mainly used for drilling soft and big drainage.

Hejian Xingtai can supply all kinds of PDC coring and non-coring bits, PDC sintering matrix bits and PDCanchoring bit. PDC bit can be widely used in the fields of geological exploration coal mining, water

We also can design PDC bits according to customer requirements, such as different geology condition,special strata and so on.

We are a professional company in supplying tri-cone bits,steel teeth bits,single cone bits,and PDC bits.

Product | Size | IADC |

PDC BIT (3 blades,4 blades, 5 blades,6 blades) | 5 1/2, 6 1/2 7 7/8,8 1/2,8 3/4 10 5/8,12 1/4 13 3/4, 17 1/2, 22, 24,26 | M223,M322,M316, M222 |

If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).